400-036-6898

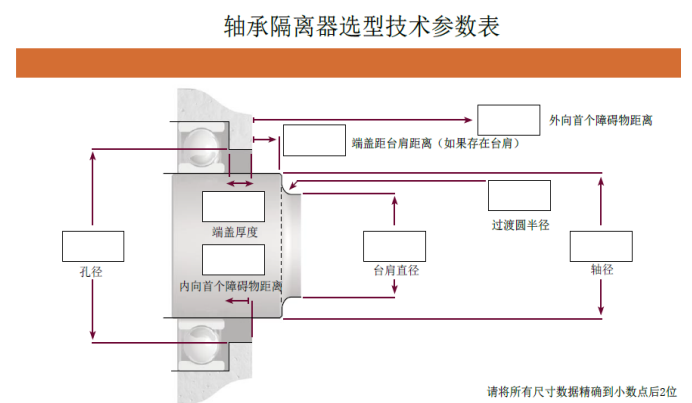

Isotec seal technology adopts modified PTFE material to process the bearing isolator, which is a cost-effective bearing protection device designed for strong corrosion conditions. It has the characteristics of non-contact, no damage to the shaft, easy installation, etc., and is suitable for splash lubrication or grease lubrication. At the same time, the dynamic ring drive ring with PTFE coating can cope with the most severe corrosion conditions, such as the sealing of acetone agitator.

The stationary ring adopts double sealing rings, which can be directly installed without special tools, and can easily replace the original lip type oil seal of the equipment. At the same time, there is a steam stop ring between the moving and stationary rings, which can prevent the external steam from being sucked back into the bearing box when the equipment is stopped, reducing the lubricant performance.

The modified PTFE material with self-lubricating property is used, which can be applied to extreme working conditions with large or unpredictable runout of the equipment shaft. Even if the moving and stationary rings have slight contact and wear during operation, it will not cause serious damage to the bearing protector itself, and avoid the high temperature or deformation caused by continuous contact of the moving and stationary rings when the stainless steel or bronze materials are abnormal in the movement of the equipment shaft, which are pumps and motors, It is an ideal choice for OEM matching of rotating equipment such as reducer or end user's sealing technology transformation.

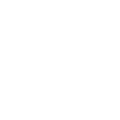

At the same time, the company can provide customized design according to the actual installation size requirements of customers, and achieve delivery within 48 hours.

1. Comply with API610 or IEEE 841-2001 standards

2. FDA food grade materials are optional

3. Upper limit of linear speed 25m/s

4. Shaft upper limit displacement 0.4 mm

5. Upper limit radial runout of shaft 0.4 mm

Bearing isolator (bearing protector) is a non-contact, wear free long-term...

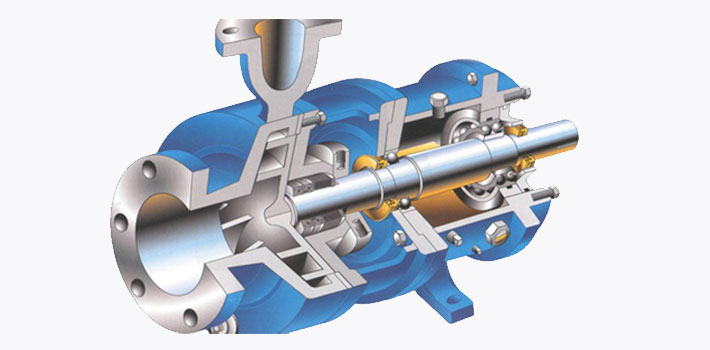

Before installing the isolator, all equipment must be thoroughly inspected....

Bearing isolator (bearing protector) is a non-contact, wear free long-term...

Telephone:400-036-6898

Telephone:400-036-6898

Address:Sanyuan, Fengxiang Development Zone, Huairou District, Beijing

Address:Sanyuan, Fengxiang Development Zone, Huairou District, Beijing

© Copyright bjisotec. All Rights ReservedFiling: 京ICP备2020034323号-1Tec:Daauu