HOME > news > Industry News

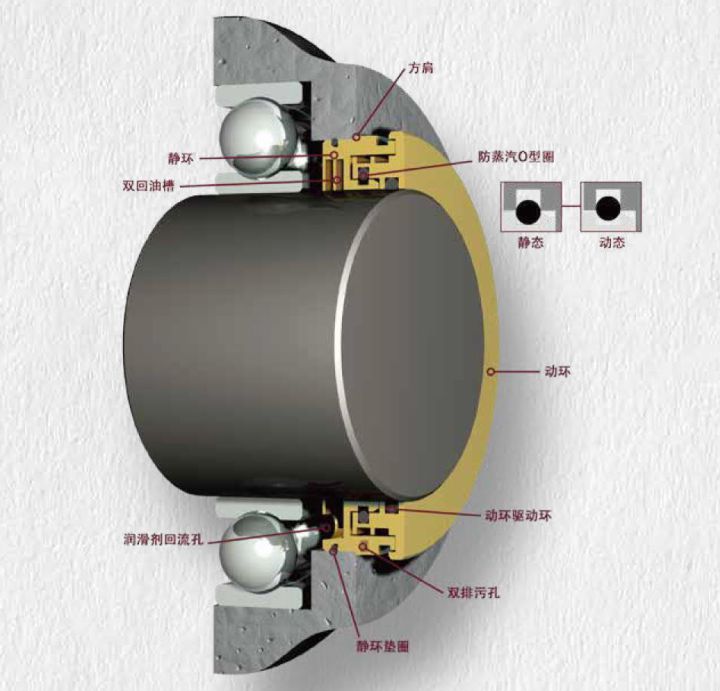

Bearing isolator (bearing protector) is a non-contact, wear free long-term bearing protector. It includes a dynamic loop and a static loop, which are integrated into one, so they will not be separated during operation.

Generally speaking, the moving ring rotates with the shaft, and the installation part of the stationary ring is pressed into the end cover of the bearing housing. The dynamic and static rings work together to prevent external pollutants from entering the bearing box and prevent the leakage of lubricating medium. The high quality bearing isolator is made of metal materials, usually brass, and is equipped with a steam blocking ring to block the free entry and exit of external water vapor, so as to prevent the external water vapor from being sucked back into the bearing box due to the internal air cooling of the bearing box when the equipment is stopped, thus reducing the lubricating performance of the lubricant. The sealing performance of the bearing isolator will not decrease over time, which enables it to provide permanent bearing protection for rotating equipment.

Bearing isolator - 6 advantages analysis!

1. Extend the service life of the equipment

90% of the bearings cannot reach the expected service life, and 80% of the bearing failures are related to lubrication. The Borui sealed bearing isolator improves the bearing operating environment, greatly extending the service life of the equipment.

2. Customized design scheme

The bearing isolator is customized and designed according to the working conditions of the equipment, which can be widely used in rolls, fans, reducers, large motors, slurry pumps, boiler feed pumps, screw conveyors and other equipment under special working conditions.

3. No shaft scratching, no power consumption

The service life of the standard lip type oil seal is 1500 2000 hours, the power consumption is about 150W, and the shaft is worn. The use of non-contact bearing protectors means reducing maintenance costs and energy consumption.

4. Improve equipment stability

0.002% of the water mixed with the lubricating medium can significantly reduce the bearing life by 48%. The sealing performance of the bearing isolator will not decrease over time, reducing the unexpected downtime and improving the operating efficiency.

5. Patent structure design

The dual oil return groove and dual dust-proof design truly achieve zero leakage and no wear. At the same time, the protection level reaches 1P66. It is a reliable bearing protection device under harsh use environment.

6. Overall solution for bearing protection and electric corrosion

The new generation bearing isolator integrating superconducting fiber shaft grounding technology is an integral solution for bearing protection of high-voltage motors, variable frequency motors and their driving equipment, which is widely used in wind power, new energy vehicles and high-end industrial equipment.

The sealing products cover 8 series and more than 100 varieties

Telephone:400-036-6898

Telephone:400-036-6898

Address:Sanyuan, Fengxiang Development Zone, Huairou District, Beijing

Address:Sanyuan, Fengxiang Development Zone, Huairou District, Beijing

© Copyright bjisotec. All Rights ReservedFiling: 京ICP备2020034323号-1Tec:Daauu