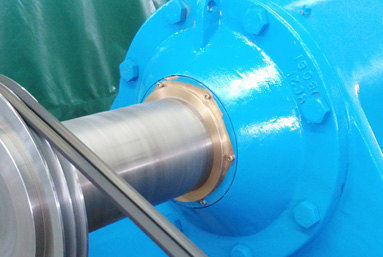

Client: Mine

Application: shaft end seal of slurry pump

Original seal: rubber V-ring

Working condition: low speed, strong vibration, heavy environmental pollution

Transformation scheme: double acting ring drive ring bearing isolator, double dust-proof design, with positioning bolts.

Reconstruction time: 2016

Transformation effect: no leakage, no pollution in oil tank, stable operation.

Although the technology is not improving, a large proportion of pump bearings still use the spring pre tightened skeleton oil seal technology to prevent the lubricant from being polluted by external water, dust and other impurities. Even now, the expected service life marked by the manufacturer of the skeleton oil seal is about 2000 hours. For a pump in continuous working condition, 2000 hours is actually less than 3 months. No one really noticed when the skeleton oil seal began to fail. However, the pump is still working continuously, and the length of operation depends on the external environment. Once the framework oil seal fails, the lubricant will be diluted and leak, which will soon lead to bearing failure. General process pumps will experience temperature changes and generate steam condensation. The condensed water vapor will be mixed with the grease to form an emulsion. Even if the water content in the grease reaches 0.0002%, the expected life of the bearing will be reduced by more than 50%. Similarly, even trace impurities or dust pollution will lead to sharp reduction of bearing life.

Fortunately, with the progress of technology, there are currently three feasible alternatives to skeleton oil seal:

1) Magnetic seal;

2) Dry running mechanical seal;

3) Composite labyrinth seal with steam barrier ring (bearing isolator/bearing protector).

Since the above technical schemes are obviously superior to the spring preloaded skeleton oil seal, which scheme is more suitable for the actual given working condition? There are four factors to be considered: relative cost, service life, sealing performance and energy consumption. Because of its non-contact labyrinth sealing principle, the bearing isolator can really realize the ultra long service life of zero leakage and the protection level of IP66. Users who pay attention to improving the stability of equipment will benefit from paying attention to the protection scheme of pump bearings, extending the service life of bearings and preventing accidental shutdown of equipment. The new bearing protection technology and scheme should be paid attention to accordingly, and should be included in the technical specifications for new pump procurement and old pump transformation when appropriate.

The sealing products cover 8 series and more than 100 varieties

Telephone:400-036-6898

Telephone:400-036-6898

Address:Sanyuan, Fengxiang Development Zone, Huairou District, Beijing

Address:Sanyuan, Fengxiang Development Zone, Huairou District, Beijing

© Copyright bjisotec. All Rights ReservedFiling: 京ICP备2020034323号-1Tec:Daauu