Client: Luanhe Power Plant

Application: circulating pump gearbox

Original seal: framework oil seal

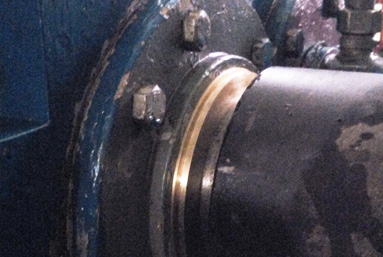

Working condition: high speed, forced lubrication, shaft scratch, short service life of skeleton oil seal.

Transformation scheme: double oil return groove+PTFE ring bearing isolator

Reconstruction time: 2016

Transformation effect: no leakage, no pollution of oil tank, and small temperature rise of bearing end cover.

The reducer is a commonly used equipment in machinery. The problem of lubricating oil leakage at the shaft end (dynamic seal) has not been solved well, resulting in lack of oil in the reducer, bearing burning or serious wear of gear pair. The resulting failures account for 50%~60% of all failures. The lubricating oil leakage is an important indicator for evaluating the quality of the reducer. The lubricating oil leakage will pose a great threat to the safe and reliable operation of the reducer. If the reducer cannot be maintained and refueled regularly, the service life of the bearing will be reduced and damaged with the loss of lubricating oil, and excessive wear of the gear will be caused in serious cases.

The skeleton oil seal is a contact type seal with simple structure, small and compact installation position, and has certain adaptability to equipment vibration and shaft diameter eccentricity. However, it requires high dimensional tolerance, surface roughness and shaft surface hardness (heat treatment) for shaft diameter and oil seal hole groove. The viscosity, oil quality, equipment service environment, temperature, etc. of lubricating oil will affect the sealing effect and service life of the oil seal. In addition, special tools must be used to assemble the oil seal so that the lip does not deform. The process requirements are high.

At present, there are many specifications and sizes of oil seals, but most of the products have poor quality and short service life. Even if the imported skeleton oil seal is used, the service life is only about 2 years. The cost of simply replacing the skeleton oil seal is often several times higher than the price of the oil seal itself. Another unavoidable factor is that when assembling the coupling, the hot assembly method is commonly used, and the temperature reaches 200~300 ℃, even higher. After the coupling is installed (due to the small spacing), the oil seal lip will lose its sealing effect due to thermal deformation and melting.

The oil slinger uses centrifugal force to throw the flowing oil to the shell wall and returns to the oil pool along the oil return groove on the shell wall. The oil slinger seal is a dynamic type seal, which is suitable for working at high speed. Its sealing performance is weakened at low speed, and it loses its sealing performance at shutdown.

The combined seal uses the above two or more sealing structures, but from the application effect, most of them are not ideal. The reason is that these sealing structures are unreasonable, or the processing and manufacturing quality of parts and components, installation process are poor.

If the reducer has a bad working environment, it must have a dust-proof structure, because:

1. The dust enters the reducer and pollutes the lubricating oil, which may cause excessive wear of the pilot gear and bearing;

2. The dust and lubricating oil are fully mixed under the stirring of the gear, which will affect the lubricating effect and fluidity of the lubricating oil;

3. The accumulation of dust and oil in the oil return passage will block the return of lubricating oil. Under normal conditions, the gear and bearing of the reducer must be well lubricated.

The bearing isolator can solve the leakage problem of the reducer by relying on its unique structural design. It can provide targeted design for different lubrication conditions (oil splashing, forced lubrication, oil immersion). At the same time, the protective capacity of the bearing isolator can greatly extend the service life of the bearing and reduce the unexpected downtime.

The sealing products cover 8 series and more than 100 varieties

Telephone:400-036-6898

Telephone:400-036-6898

Address:Sanyuan, Fengxiang Development Zone, Huairou District, Beijing

Address:Sanyuan, Fengxiang Development Zone, Huairou District, Beijing

© Copyright bjisotec. All Rights ReservedFiling: 京ICP备2020034323号-1Tec:Daauu